All posts in 2013

Cyr Wheel Skinning: Not all tubing is the same!

I’ve ordered a few different types of skin for my cyr wheels. On one wheel, it has pieces from two different batches and kinds.This has shown me that one is much better! Both are 1.5″... [read more]

Dec

30

2013

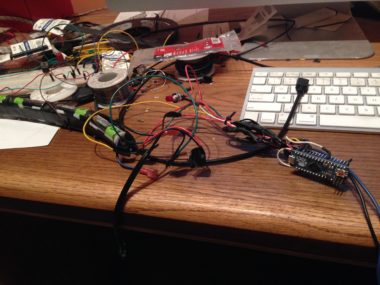

LED Cyr Wheel v1 Problems

Some of the problems with my original LED cyr wheel: 1. LEDs are dying, from me stepping on them. I took one of the bad sections apart, and it seems to be because some solder... [read more]

Dec

29

2013

Photography: Half Dome at Night

Half Dome at Night 12-25-2013. About 10 minute exposure. I was freezing cold that night; it was about 28F.

Dec

28

2013

LED Notes / LED Cyr Wheel v2

I’m investigating LEDs for another LED cyr wheel (v2). Here is my first LED Cyr wheel and a video. I figure I’ll just make my notes on my blog for others to benefit. Goals: Individually... [read more]

Dec

28

2013

Sunset from El Capitan, Yosemite

Sunset from El Capitan, Yosemite 12-25-2013. 5 exposures taken with the Canon 5D.

Dec

27

2013

Adhesives

I’m investigating adhesives, and ways I can bond the plastic PVC tubing on cyr wheels back together. I want to cut the plastic tubing, and embed LEDs under it for some cool effects. For my... [read more]

Dec

22

2013

Oil pan fixed on my Harley

I have an old Harley, and it has leaked oil for quite a while. I finally decided to do some maintenance on the old bike and took off the oil pan and stripped the paint... [read more]

Dec

21

2013

No Fossil Fuels Sticker

I finally cleaned up my “no fossil fuels” sticker for EVs! I just ordered a few stickers (8) from StickerYou — http://www.stickeryou.com/ — the place has a decent website, but they have a terrible security... [read more]

Dec

20

2013

Master Bathroom Remodel Almost Done!

Shower door installed (I paid someone to measure and install it…it was much easier than me doing it myself): Cabinet doors and hardware installed. Waiting for the counter top to be fabricated…

Dec

13

2013

Geared Hub troubles

I have several KH/Schlumpf geared unicycle hubs. They allow me to have two different speeds, and really have been a game changer for unicycling. One of my older hubs started to have bearing failure, causing... [read more]

Dec

11

2013

Adding a disc brake to an older KH24 mountain unicycle

I have an older KH 24 mountain unicycle that doesn’t have the disc brake mount on it. During my Switzerland/Italy tour in the summer of 2012 I used a D-brake adapter (from unicycle.com) and KH... [read more]

Dec

11

2013

Master Bathroom Remodel: Shower Tile

I’ve been rather slow to update my blog. It is mainly for myself to remember what I did. After I finished the shower pan, I painted this red waterproofing membrane on the areas that might... [read more]

Dec

11

2013

Making the LED Cyr Wheel / Roue Cyr – version 1

Here are my rough notes about making my LED cyr wheel (version 1). A Video can be seen here. Edit: 12/28/2013: Here are some problems I am having with this LED Cyr Wheel v1 I... [read more]

Oct

21

2013

Master Bathroom Remodel: Stained & Finished

I’ve had this done a while…but here are some pictures of the bathroom cabinets and vanity. This is mainly for me to remember and look back on my blog and see what I did to... [read more]

Oct

16

2013

LED Cyr Wheel / Roue Cyr videos

Here are some videos of the LED Cyr wheel at Burning Man 2013 Spencer also put together a compilation of it here (with a Fire Cyr wheel and LED Unicycle!):

Oct

8

2013

Master Bathroom Remodel: Tile Rendering

Playing with tile options (ordered!) and still working on the bathroom remodel project. Cabinets have the finish applied, and I’m doing drywall work. Then plumbing…then tile.

Sep

21

2013

Bug Down again.. and don’t use Fortes Brothers Towing in Cupertino!

First off, don’t use Fortes Brothers Towing in Cupertino! They are terrible, and don’t know what they are doing. AAA called them to tow my bug home from work (in Cupertino), and the guy had... [read more]

Sep

12

2013

LED Cyr Wheel Pictures

Here are a few pictures of my LED cyr wheel. I setup my Canon 5D on a tripod and my dad hit the shutter button (via a remote). In general, about 0.4s exposure, f2.8, iso1250.

Sep

12

2013

LED Cyr Wheel

I made an LED cyr wheel! Details coming soon. I brought it to burning man 2013 and camped with my “Circus Boot Camp” friends. Ray took this picture:

Sep

4

2013

Master Bathroom Electrical

I tore out the rest of the drywall, and removed the old bath tub. I then started redoing the electrical in prep for the new cabinet. The electrical switches were on the wrong side; they... [read more]

Jul

19

2013

Master Bathroom Remodel: Drawers Finished

I finished my drawers; sprayed 4 coats of Target Coatings Water based lacquer on them. (EmTech 6000). It took a whole gallon to do them all..and ran out right at the end. These are mainly... [read more]

Jul

19

2013

Bathroom Remodel: Moving the Water Ins and Outs

The bathroom remodel is a slow project when I do everything myself. Today I worked on finishing my drawers while also moving the plumbing for my sink. It’s hard to tell, but I cut out... [read more]

Jul

5

2013

Bathroom Cabinets: Floating Vanity Cabinet Design

I want my bathroom cabinets to “float”. The top one floats 2″ in the air on top of the bottom cabinet, and the bottom cabinet floats 3″ in the air off the ground. The right... [read more]

Jul

5

2013

Master Bathroom Cabinets; Drawer Faces and Doors

Still working on stuff. Playing with stains; left side is 1/2 cherry ply, right is cherry wood. Bottom has a maple gel stain, top has pennsylvania cherry gel stain. Cutting all the face pieces to... [read more]

Jun

25

2013

Master Bathroom Cabinets – Building Drawers

My woodworking project continues! I planed a bunch of maple to 5/8″ thick my drawer thickness. I went with 5/8″ instead of 3/4″, since my top drawers should appear more “dainty” as they are small.... [read more]

Jun

9

2013

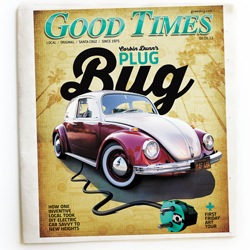

Good Times!

A local weekly newspaper in Santa Cruz, The Good Times, did an awesome article on my VW bug and myself. Check it out here: The Plug Bug and Corbin Dunn. (Link updated on October 4,... [read more]

Jun

9

2013

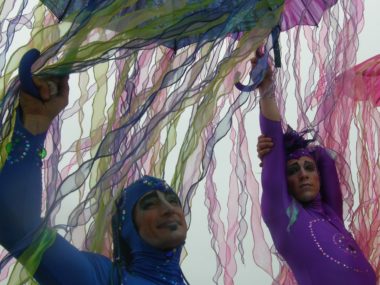

Circus Work

I recently met up with Gregangelo from Velocity Circus! I’m going to be doing some circus work with him, which is super-exciting. Gregangelo has some of the most awesome costumes. Here’s when I was a... [read more]

Jun

9

2013

As an Amazon Associate I earn from qualifying purchases.

(c) 2008-2025 Corbin Dunn

Subscribe to RSS feeds for entries.

45 queries. 0.201 seconds.