Videos: Shallow Flow Bowl – CNC Woodworking Projects

This is my “Shallow Flow Bowl” design that I did a while back in Fusion 360. I decided to make a few of them out of wood for sale on Corbin’s Workshop and Etsy and... [read more]

Jun

29

2023

Video: Wood Heart Boxes

I made a few more of these boxes and finished up a video on the whole process. This was one of the first projects on my Avid CNC that I got earlier this year. Some... [read more]

Jun

9

2023

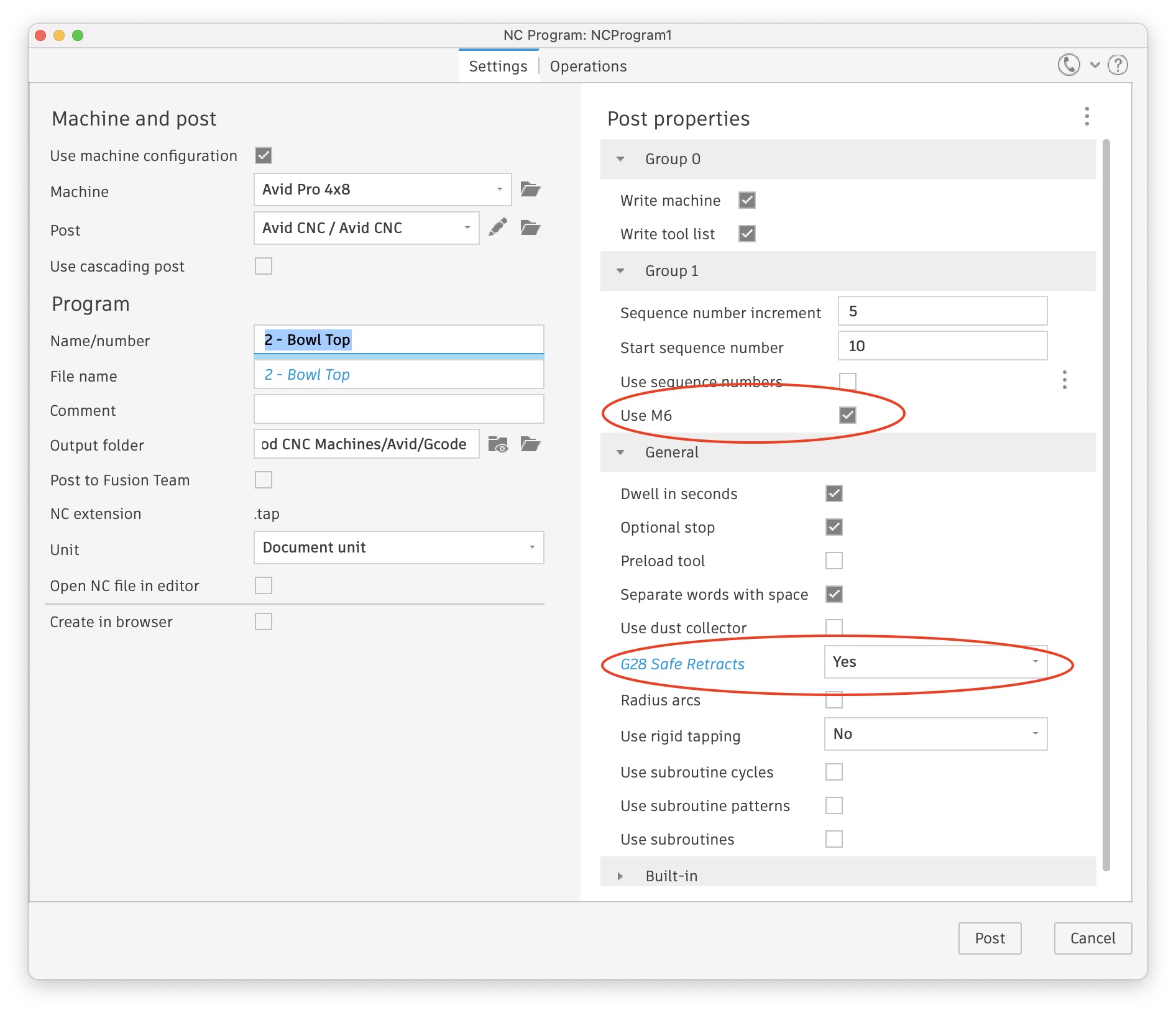

Avid CNC ATC Post Processor for Fusion 360

If you are using an Automatic Tool Changer (ATC) with an Avid CNC then you have to customize or install a new post processor to make it work properly in Fusion 360. UPDATE: the current... [read more]

May

27

2023

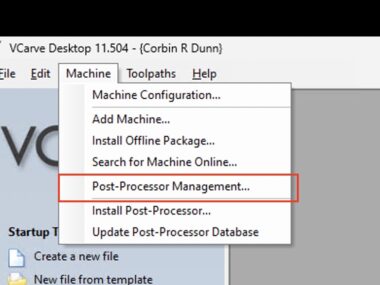

Avid CNC ATC Post Processor Setup – Vectric VCarve / Vectric Aspire

If you are using an Automatic Tool Changer (ATC) with an Avid CNC (Mach 4 or Centroid), then you need to customize the post processor for Vectric. The one provided by Avid is not right!... [read more]

May

21

2023

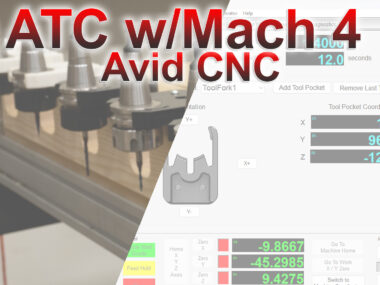

Video: Mach 4 Setup for an ATC

In one of my last posts, I discussed how I setup the hardware for my ATC on my Avid CNC. This video describes the software side of things. I’ve been working on this software for... [read more]

May

19

2023

Video: How to Make an ATC Tool Rack

I needed a tool rack for my HITECO ATC spindle on my Avid CNC machine. I experimented with 3D printing some holders, but I felt like they were too weak. So, I ended up machining... [read more]

May

9

2023

How to Setup an Automatic Tool Changer (ATC) on an Avid CNC using Mach 4

Video link: ATC Setup on Avid CNC This is a companion article for the above video where I talk about setting up an Automatic Tool Changer (ATC) on a CNC machine. For the Mach 4... [read more]

May

3

2023

How to Tram a CNC Spindle / Router

When you build a CNC the spindle or router may not be perfectly aligned to the table. You have to tram it, or align it to the axis that it will move along. This is... [read more]

Apr

28

2023

Video: Precision with an Avid CNC Build

Video link: Ep3: Avid CNC Build Getting Precision and Accuracy Precision and accuracy are really important to a CNC machine. I wanted mine to accurately flatten a piece of wood down the entire length of... [read more]

Apr

21

2023

Video: Building a Heavy Welded Steel CNC Table

Direct video link: Avid CNC Steel Table Build One of the biggest complaints of the Avid CNC is that the table isn’t heavy enough. A heavier table will help produce better cuts on a CNC... [read more]

Apr

18

2023

Avid CNC vs Phantom CNC, Laguna, Shop Sabre, Etc

Textual link to the video: Don’t Buy the Wrong CNC – Why I got an Avid CNC This video is almost 20 minutes long and I go into details on why I got an Avid... [read more]

Apr

8

2023

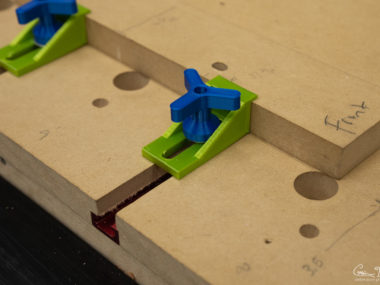

Low Profile CNC Toe Clamps – 3D Printed

I needed a better way to hold down my workpieces onto my CNC table. I had seen some low profile clamps that the people have done, but they were all designed for a t-nut system,... [read more]

Apr

3

2023

Heart Box Wood Variations

I’ve been doing some variations of the heart box with different woods. This one has a cherry wood base with the same wave design I did in the original wood heart box. I used maple... [read more]

Mar

29

2023

Heart Box – Cherry Wood and Madrone Wood Wave

I’ve been working on setting up a new CNC machine, and this is one of the first projects I did on it. It is a variation of the epoxy and wood heart boxes I did... [read more]

Mar

24

2023

Walnut Spatula and Spoon

So far I have made one pair of the spoon and spatula utensils to sell. These are made from walnut with a madrone wood inlay in the shape of a rose. They are the same... [read more]

Mar

18

2023

CNC Woodworking: Madrone Spoon with Wood Inlay

I decided to make a custom spoon to match the Wood Spatula I shared in my last post. I’ve only made a few of them with the rose inlay, but I do hope to make... [read more]

Mar

8

2023

Madrone Wood Spatula with Walnut Wood Inlay

I’ve been working on some utensil designs, and the first thing that I made is a wooden spatula. The spatula itself is curvy and round, which is contrary to a lot of spatulas that I’ve... [read more]

Jan

24

2023

Video: Heart Box – CNC Woodworking

In the last few posts I shared some photos of my heart box. The first prototype one was made from cherry wood with Bora Bora blue epoxy and the second pair was made with purple... [read more]

Jan

14

2023

Heart Box – Cherry Wood Box with Purple and Ghost Blue

The first heart box, Cherry with Bora Bora Blue, was a prototype that turned out awesome. However, I felt like there were ways to improve things, especially when my wife gave me some invaluable feedback.... [read more]

Dec

30

2022

Heart Box – Cherry with Bora Bora Blue

Update: Available for sale on my store: Corbin’s Workshop or Etsy: Box on Etsy I thought it would be fun to add a lid to my heart bowls and turn it into a box. The... [read more]

Dec

20

2022

Corbin’s Workshop Store on Etsy

I decided to take the plunge and list some of my things on Etsy. Check out my store: CorbinsWorkshopStore for Woodworking on Etsy. I was avoiding this, due to the 7% fees they charge, and... [read more]

Dec

6

2022

Video: Heart Bowl Packaging

Lately I’ve been making several heart bowls to post for sale on my website: Corbin’s Workshop. To ship them, I normally would haphazardly wrap up the product in a bunch of old packaging material, put... [read more]

Dec

1

2022

Heart Bowl – Madrone with Lava Shimmer

My last heart bowl (madrone with bora bora blue) was also made from madrone wood, and this one turned out awesome! I decided to experiment with some new mica powder pigments, and I thought a... [read more]

Nov

29

2022

Heart Bowl – Madrone with Bora Bora Blue

I’ve been working on making a few more heart bowls to have some inventory for sale on my website. This is one of the first ones! This bowl is made from madrone wood. But not... [read more]

Nov

28

2022

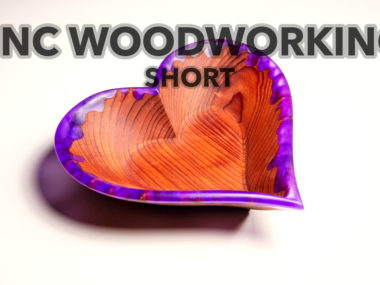

Short Video: Heart Bowl – CNC Woodworking

I made this Short (aka: TikTok or Reel) from my full length Heart Bowl CNC Wooddworking video over on YouTube.

Nov

9

2022

Short: Epoxy Drip Bowls

This is a short made from my original Epoxy Drip Bowls video. Original post: Epoxy Purple and Gold Drip Bowls Original video: Epoxy Drip Bowls on YouTube

Nov

5

2022

Photography: Sun Setting Over Lanai

I took this photo in Lahaina, Maui, Hawaii. The island of Lanai can be seen in the distance with the sun setting behind it.

Oct

26

2022

Short Video: Batman Box CNC Woodworking

I’ve been reworking some of my earlier YouTube videos into “Shorts/Reels/TikToks”. It’s interesting because I get a lot more views. Check out the original video: https://youtu.be/nOVbJVuCh5k As of today, the original video got 3700 views,... [read more]

Oct

25

2022

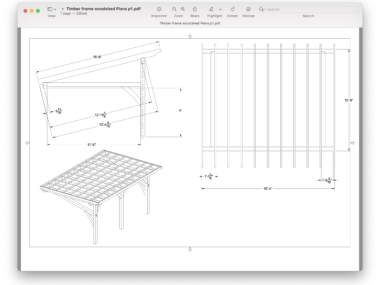

Video: Timber Frame Woodshed – Learning & Building

My last post I put up the plans for my timber frame shed – they are super generic and the minimal information I needed to build the wood shed. Here’s a complete video on the... [read more]

Oct

14

2022

Timber Frame Woodshed “Plans” & CAD

Soon I’ll be posting a video about making my timber frame woodshed. For now, here are some links to the plans. I use the term a bit loosely; it is the minimal amount of dimensions... [read more]

Oct

6

2022

Borneman Timber Frame Layout Guide – 3D Printed (Free STL Download)

Download all the files for free over on Corbin’s Workshop: Borneman Layout Guide I’ve been fascinated with timber framing for a few years. This is when you use lots of big pieces of wood, called... [read more]

Sep

6

2022

As an Amazon Associate I earn from qualifying purchases.

(c) 2008-2025 Corbin Dunn

Subscribe to RSS feeds for entries.

45 queries. 1.127 seconds.