All posts in 2012

Plug Bug: Bad cell

Well…lost a good post on my bad cell. Long story short: one cell has been sagging really badly, so I replaced it. About 20,500 miles. The bad cell had high resistance, and was swelling at... [read more]

Dec

31

2012

Plug Bug: Transmission replaced

Some updates on the electric bug. Back on Thanksgiving I was on a slight hill pointed downwards (at Nathan’s house). I put the car in reverse, but missed the gear and stepped no throttle. The... [read more]

Dec

31

2012

BMS Display part 4 – graph

I updated my BMS display software to actually respond to the buttons I have. Now I have another screen of data, graphing each cell. The graph goes from 2.0v at the bottom to 4.0v at... [read more]

Nov

25

2012

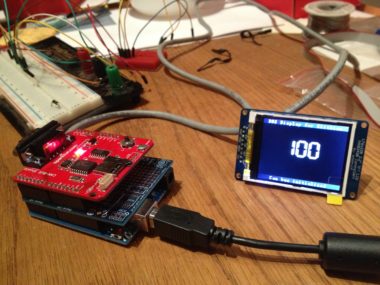

How to make an Elithion BMS Display

Here is directions to make your own Elithion BMS Display. Use at your own risk! Parts required: Arduino UNO – (the Leonardo will NOT work) – ~$30 Sparkfun CAN Bus shield– $45 Adafruit proto shield... [read more]

Nov

23

2012

Elithion BMS Display – part 3 pictures

Elithion BMS Display in my car, showing the basic features (State of Charge, amps out or in, pack voltage, min/avg/max cell voltage): Notice there are 5 buttons below; those will be wired up to the... [read more]

Nov

23

2012

Elithion BMS Display – part 2

I did a lot of work on my display and now it is working! If anyone else is interested in the code, it is all at https://github.com/corbinstreehouse Good information to learn more about CAN bus... [read more]

Nov

23

2012

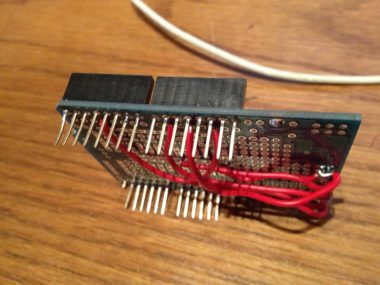

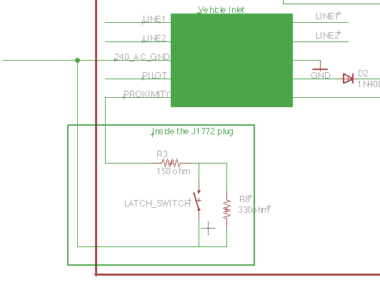

Plug Bug: Charger Control Updates

I made some updates to my charger control project. I discovered my EVSE didn’t like the way I was testing for the proximity switch on the plug latch to be closed. Whenever the Arduino was... [read more]

Nov

17

2012

Elithion BMS Display – part 1

I want a better BMS display for my car. I have the Elithion BMS “Pro“, which has worked pretty well in my conversion. Sometimes it gives faults earlier than I would want, and sometimes I’ve... [read more]

Nov

14

2012

EV Converstions and white Clean Air Stickers

In California, EVs can get a clean air sticker and the right to use the carpool lane while solo (also called the High Occupancy Vehicle lane, or HOV). I love the fact that California is... [read more]

Nov

9

2012

Electric Bug: Charger Control – Design

Based on my requirements, I made some hardware the will more intelligently control my Manzanita charger. It is powered by an Arduino, and has a little LCD to tell me what is going on and... [read more]

Nov

8

2012

Electric Bug: Charger Control – What I want

I’m using the Manzanita Micro PFC-30 charger to charge my car. It basically has technology from 10 years ago, and drastically needs some updates. Now, they are slowly updating the charger, but it still doesn’t... [read more]

Nov

8

2012

More old car work!

I had to do some work on the Electric Bug lately. I replaced the right rear wheel bearing (I did the left a while ago). It was starting to get sloppy. My steering box was... [read more]

Nov

5

2012

Cyr wheel @ Burning Man

It’s funny to be looking on the internet and find a video of yourself that someone else took at burning man! Here’s me at Circus Boot Camp 2012:

Oct

27

2012

Where to buy a cyr wheel / roue cyr

Last update: September 2021 Where to buy a cyr wheel / roue cyr / simple wheel. Do you want to buy a cyr wheel? Here is a list of all the known retailers or manufacturers. There... [read more]

Oct

27

2012

Roue Cyr at Burning Man 2012

Roue Cyr at Burning Man 2012 (That’s me!) Photo by Tristan Savatier – www.loupiote.com – used by permission. (Thanks Tristan!)

Oct

26

2012

Roue Cyr v3

I needed a 5 piece wheel for traveling with my roué cyr and decided to make a new one for the Chicago Big Wheel Weekend. My prior wheels were three pieces, but five seems to... [read more]

Oct

19

2012

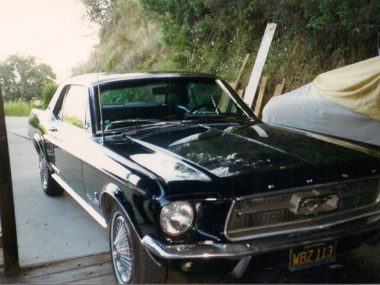

Old times…

For about 7 years I drove a 1967 Ford Mustang around. I miss that car! It would have been a cool conversion to electric. I just scanned some old pictures I came across and thought... [read more]

Oct

1

2012

Homesteading: Easy apple coring

So I was manually coring some apples at my house to dry them using a knife and commenting to my friend Rosannah how much of a pain it was to do so. She suggested using... [read more]

Oct

1

2012

Plug Bug: PFC-30 Charger Failed Again

Back in May 2011 my Manzanita Micro PFC-30 Charger stopped charging for no apparent reason. It recently just happened again! And darn it, it was out of warranty *again* and I had to pay to... [read more]

Sep

25

2012

Cyr Wheel Performance at Berkeley Juggling and Unicycle Festival

Here’s my act I made up. Thanks to Jay for filming it!

Aug

20

2012

Midnight Burn – Roue Cyr / Cyr Wheel

One of my friends, Corinne, put on a fundraiser for the 418 Project (a dance studio in Santa Cruz). It was a blacklight/LED performance, followed by a midnight fire show. I did a simple cyr... [read more]

Aug

17

2012

Photography: Aged Venice

Aged Venice From Venice, Italy. 07-25-2012. 5 exposures taken with the Canon 5D.

Jul

29

2012

Photography: Train Station Adjacent, Venice

Train Station Adjacent, Venice From Venice, Italy. 07-24-2012. 5 exposures taken with the Canon 5D.

Jul

27

2012

As an Amazon Associate I earn from qualifying purchases.

(c) 2008-2025 Corbin Dunn

Subscribe to RSS feeds for entries.

45 queries. 0.192 seconds.