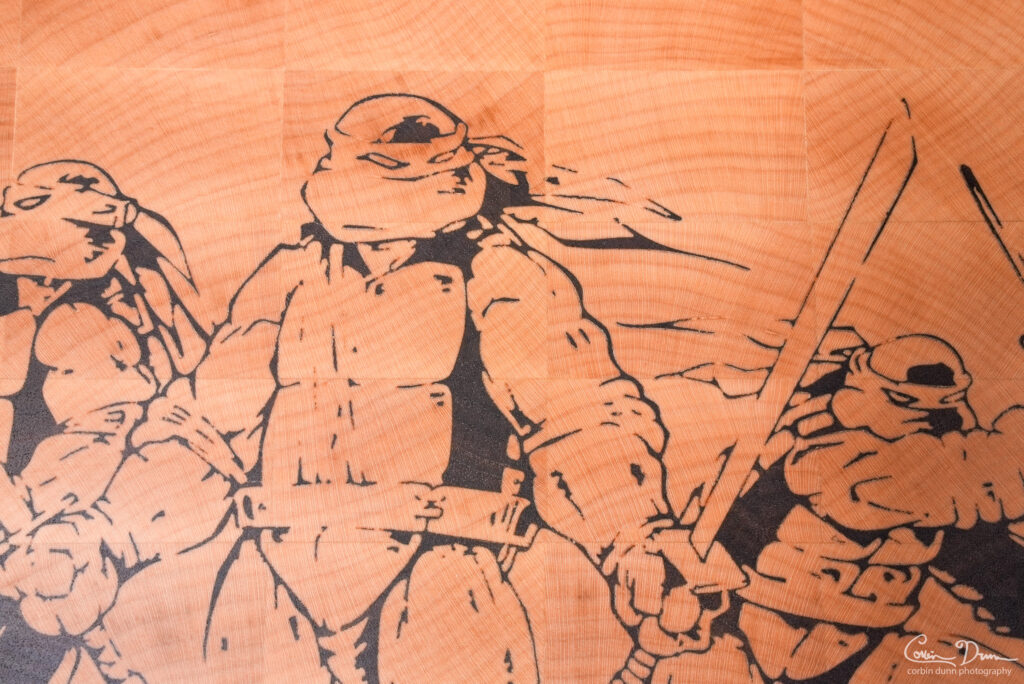

The TMNT Cutting Board

One of the reasons I got a CNC machine was to make wood inlay cutting boards. There are a lot of people making them, but the most famous person is probably Nik, from Broinwood. Check out Nik’s Broinwood Instagram for an amazing array of his work. It is really inspiring!

I’ve been doing wood inlays for quite some time, but most of them have been small inlays on curved surfaces, such as at the end of my wood utensils. These have been good practice for building up to making something larger, as it is generally harder to do small detailed inlays and it is even harder to do a curved inlay.

Inlays are more difficult in the face grain of wood; the wood tends to chip out. A lot of cutting boards are made from the end grain of wood, which avoids chipout. End grain cutting boards are also supposedly better for knives, as the fibers sort of move aside when you cut on them, and the wood tends to “self heal”.

I decided I wanted to get into making some cutting board designs, and I’ve had a v-carved Teenage Mutant Ninja Turtles design that I always liked a lot and thought it would make a good cutting board.

I recorded a time lapse of the video and put it up on YouTube: TMNT Board Time Lapse and Instagram: TMNT on Insta. The Instagram one has gotten a lot more views than YouTube.

I used a 15-degree v-bit to carve the design. The v bit can “pull up” in the corners and produce sharp edges. However, I lost a bit of detail in the design, particularly in the middle area..and this was just due to me machining it flat too soon. Gluing in the inlay caused the board to warp and cup upwards in the middle…and I machined it the next day when it was still warped, killing a lot of detail in the design. I should have just waited two full days, as the glue would fully dry and the board would have returned to normal. Ah well, lesson learned! I did some informal polls on Facebook and I guess this is quite common: wait at least 48 hours, and up to 3 days after gluing.

The board is primarily maple end grain (the light wood) with walnut end grain as the dark part. Maple easily stains, and we’ve been using the board for a few months and it already has quite a few stains on it.

The design was created in Adobe Illustrator, using an image trace of a TMNT drawing I found or scanned (I forget which I did). The toolpaths were done with Vectric VCarve; not my favorite program for CNC toolpaths / CAM, but I was having trouble getting my V-bit inlay plugin to do all the details. Since this point, I’ve reworked the plugin a lot and made it work a lot better for detailed designs. The next cutting board, titled “Hibiscus Cutting Board”, was done entirely with my plugin.

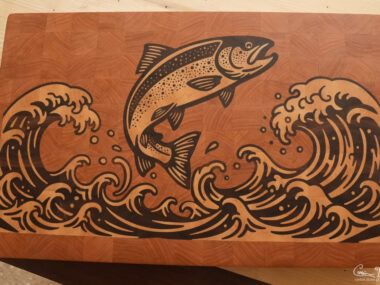

[…] my last post I talked about the TMNT Cutting Board, which was one of my first inlay cutting board designs created with the CNC machine. It was a […]