Modern Woodworking: A Curved Bookcase (Really for Shoes, Not Books)

We needed a better entry way organization system for our house. Something to store shoes, jackets, and our winter gear: hats, gloves, scarves, socks and any other miscellaneous stuff that collects by our front door.

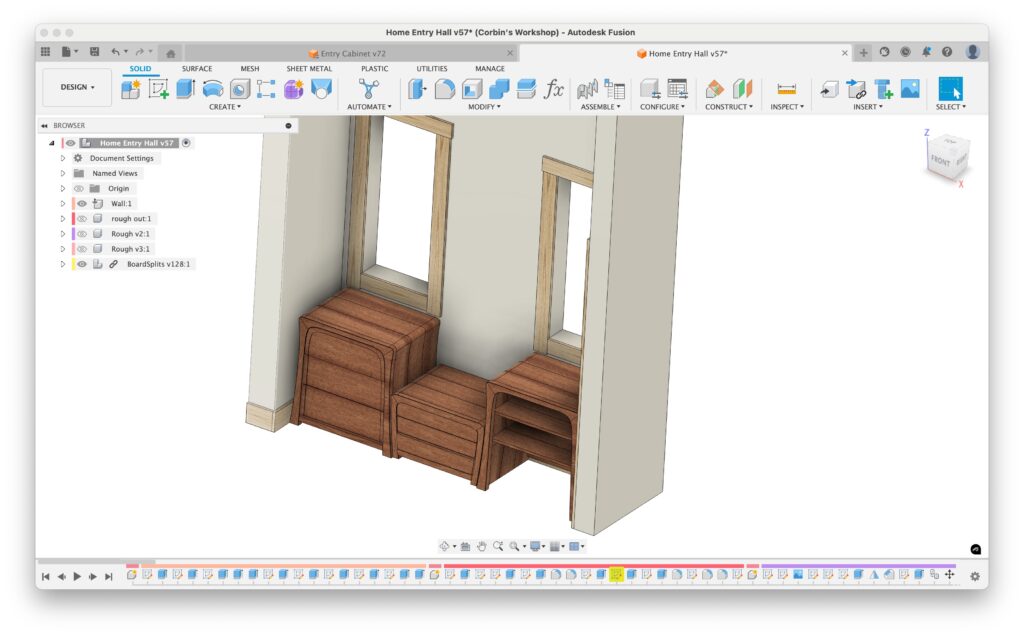

I spent a lot of time on the overall design, doing a few iterations based on some feedback from my wife. Like usual, I did all the CAD work in Autodesk Fusion, and my video talks about one of my main design aspects: curves that are fluid. Specifically, I focused a lot on the continuity of the curves, trying to go for G3 continuity to make it have a more pleasing look. Although, the top is not quite G3, but it is hard to notice. There are a lot of websites that discuss G0, G1 and G3 continuity — give it a Google if you are curious about, but be warned: you’ll start paying more attention to curves once you know more about them. Top industrial designers, like the ones at Apple who designed the iPhone, created very specific curves, and it is because they are atheistically pleasing.

The size of the cabinets is based entirely around my entry way nook dimensions. I drew up all the walls in CAD, and then did a “component reference” to the trio of cabinets which exist in another file. I did all the main work in the separate file, but keep an eye on the overall entry way design to make sure things were going to fit and look good. The front door is on the right of the above screen shot, and jackets will hang in the middle area between the windows. The middle cabinet will do double duty as a chair height stool for putting on shoes. The right shelf cabinet is a glorified book case that is missing the bottom shelf, simply to allow me to shove big winter boots under neath it, and store summer shoes on the top shelves.

My entry way has a small nook on the left and right side, so I’ll mirror the design on the other side of the room, creating a total of 6 cabinets.

I started the build by making the shelf cabinet first, as it would be the easiest. It’s primarily solid cherry wood, but the back is cherry plywood (MDF core) just because I didn’t want to deal with wood movement. This shelf cabinet is what you see me building in the first video, and as usual, I rely a lot on my CNC. But I also heavily relied on the Domino joiner for doing floating domino tenons.

I used to hate the Domino, but now I love it. I felt it was such an expensive and niche tool that was nothing more than a glorified biscuit joiner. But in reality, it is so much better, and so much more versatile than I could have ever imagined. I can do floating tenons with my CNC, but the time to set everything up starts to be enormous when you have to do CAD and CAM for each mortise. It would also potentially be really difficult to clamp down certain pieces that are curved on the backside, as the top would have to be perfectly parallel to the CNC’s x/y axis of travel. Bringing the small Domino to the workpiece is much faster, and more flexible in how I can do the cuts. This is particularly useful in wood that warps slightly after machining; I can use dominos to force them back into proper shape, and I did just that in this piece.

Currently I’m working on building another shelf type cabinet, and then I’ll tackle the drawer based ones. I haven’t quite settled on a drawer front design, so what you see in the renderings isn’t what I’m actually planning on doing. I have some ideas for textured fronts and custom wood pulls, but I have to actually do the design that I’m picturing in my mind.

Other interesting fact: I filmed this YouTube video entirely on my iPhone 16 Pro. Usually I would use my Sony a7 mirrorless camera, but I wanted to try something new. The iPhone was a lot easier to just grab and use…and I think I’ll combine the two to get the shots I want.

Eventually I’ll post the files for everyone to download…stay tuned to get em!

[…] My blog has more details about this piece: Modern Woodworking: A Curved Bookcase. […]

[…] Back in September I finished two of these Curvy Cabinets with Drawers to match my last bookcase style shoe rack. […]