Building a Wall Cabinet / Medicine Cabinet

I just finished building a medicine cabinet for my bathroom. I wanted something that matched the mirror frame design that I did about a month ago.

This project file is shared over on Corbin’s Workshop as a free download: Digital File: Medicine Wall Cabinet – Autodesk Fusion File.

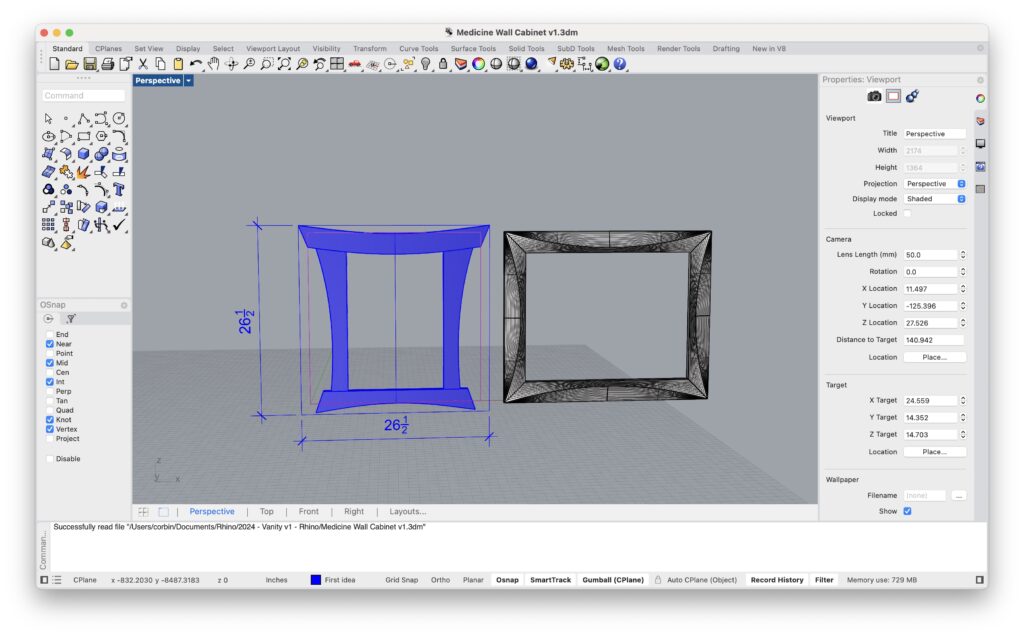

Overall, my design influence is Japanese architecture, but this is a 100% original design made from scratch. I started out by playing with shapes in Rhino. Rhino is a lot more organic and flexible to tweak 3d models. I also like how it handles curves; they are just a bit easier for me to tweak and manipulate. I could also add in my mirror frames to get a feel for size proportions.

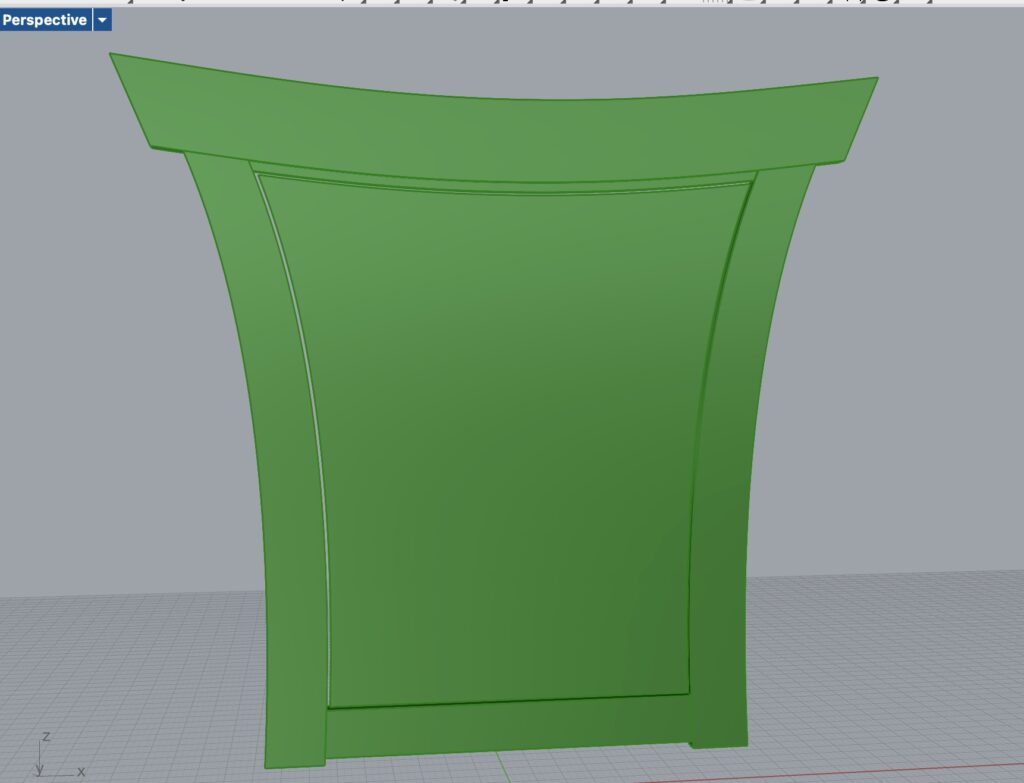

Initially I designed a curved door, as seen below in green. I really wanted this to work, and it would have looked amazing, but it would be really hard to make the door hinges. The pivot point for it would cause some sort of issue, and two hinges would have to move at different rates in order for the door to open. A single hinge would work, but it would also cause issues with the door going inside the carcass body when opening, and I wasn’t sure if a single hinge would be strong enough to hold it.

So, I abandoned the curved door idea and went with a straight edge door because I knew it would work.

Once I had the basic shape, I exported it as an STL and imported that in Autodesk Fusion 360. I didn’t want to do the machining from the STL, so I made a new “Sketch” in Fusion and traced over all the curves using Bezier paths. I could have just done this in the first place, and skipped using Rhino, but Fusion makes it a little more difficult to rapidly prototype different shapes. Plus, I wanted to spend more time learning Rhino’s 3D capabilities; I still struggle with a lot of basic things that I can easily do in Blender or Fusion.

The carcass build is a basic rectangle dovetailed box. I think this project could be taken to the next level by having the body follow the curves. I might have done this if it was a more prominent piece of furniture, but I didn’t think it was worth the time for my bathroom, in particular when the depth of the cabinet is so shallow.

I made some mistakes along the way, and I did buy a Festool Domino to cut some floating mortise and tenons. I ended up returning the Domino, as it had some alignment issues, and I think I got a lemon of a tool.

And now, a few photos of the finished piece.