Corbin V-36

It’s partially an experiment to see how light I can make it, yet still be strong and not flex.

I did a 3d model in Sketchup, and printed it full size. I then machined a jig to hold things in place. Here’s a video explaining the jig:

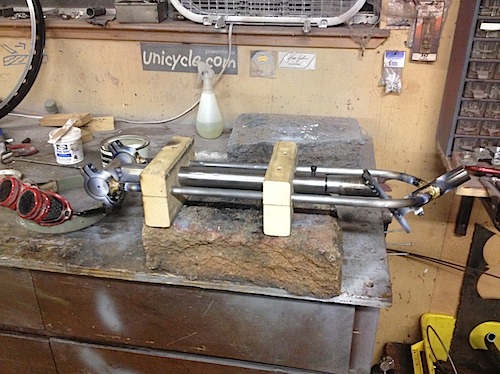

And some pictures. The jig setup for my my main seat post tube:

Experimenting with bending:

I’m using cro-moly tubing, 1/2″ OD by .049 wall thickness. It is too small of tubing, and the frame flexes when going up hills. I’m going to use 7/8″ tubing next, and try to re-enforce this frame.

Working the corners in my jig:

Jig and frame almost setup to weld the front post tube:

Clamped together, and brazing started:

Popped out of the jig and a test fit:

Setting up the main seat post:

After it was brazed on:

Horizontal support, bent to match the tire diameter, brazed on, and a test handlebar tossed on:

The frame flexes *a lot* going uphill. I have to use larger tubing for the seat post to fix that. I brazed on some lower supports to try to prevent flex, but it didn’t help much. I’m going to braze on another tube really close to my seat post to try to get this frame to work. Then, if it does, I’ll make another one with thicker tubing.

Due to heat distortion, I had to ream out both tube holes to get the stuff to go into them.

Nice project. The flex issue is an interesting one to think about. The core problem is that for a 36″ frame, the tubing runs are a lot longer than bike seat/chain stays–althugh if I think about it, even my 26″ Rick Hunter, which also uses half-inch CrMo tubing, is pretty flexy. Wider tubes will probably help, although you have to be concerned about knee clearance issues. A wider hub would help, too, but unfortunately we’re stuck with 100mm hub spacing if we want to use the Schlumpf. 100mm spacing is way narrower than bike rear triangles, which lately have gotten as wide as 170mm on fat bikes, with 135mm as the typical bike standard.

You can make a brass/steel plug for the seatpost to help prevent distortion due to heat. I use some that are “purge-able form Sputnik tools: http://www.sputniktool.com/small-tooling/heat-sinks/ if you do welding with something like titanium.

Also, as you move up in diameter of tubing you should be able to reduce the wall thickness. I wonder if bike specific tubing in higher tensile strength might help. Aircraft 4130 is in the 85,000–110,000 psi (590–760 MPa) range, where some of the higher end bike stuff is around 200,000+ psi. I have success building bikes with OX Platinum from True Temper: http://www.henryjames.com/tubing.html. S3 is pretty cool stuff, maybe some chainstay material might be long enough with a large sized fork crown. Butted tubing may also say you some weight without losing strength.

Another idea is to move to thin titanium, but use a bunch of it in a space frame/bridge triangle setup like the Moulton: .

.

How thick of tubing can you make the legs and still have clearance for riding? You might be able to make some oval tubing from round stock to keep width down.

Have you calculated the weight of the frame and considered adding a third frame in the middle of the other two? I am curious how the weights compare.

Corbin, small tube is not the optimum for weight/strengh ratio, may be you should contact Roger, he has some experience on his previous 36″ frame. Adding a tube close to your seat and up to T-bar should help. Enjoy !

What is the mode of flexing? You should try building up a space frame as Bronson suggests… it would look cool :)

J-man, the flex is side to side, causing the tire to rub on the frame.

Didier, Bronson — yeah, all great ideas! I’m going to explore some of these options.

corbin

Just for reference, the Telford was 5/8 .035